Customized electronics manufacturing

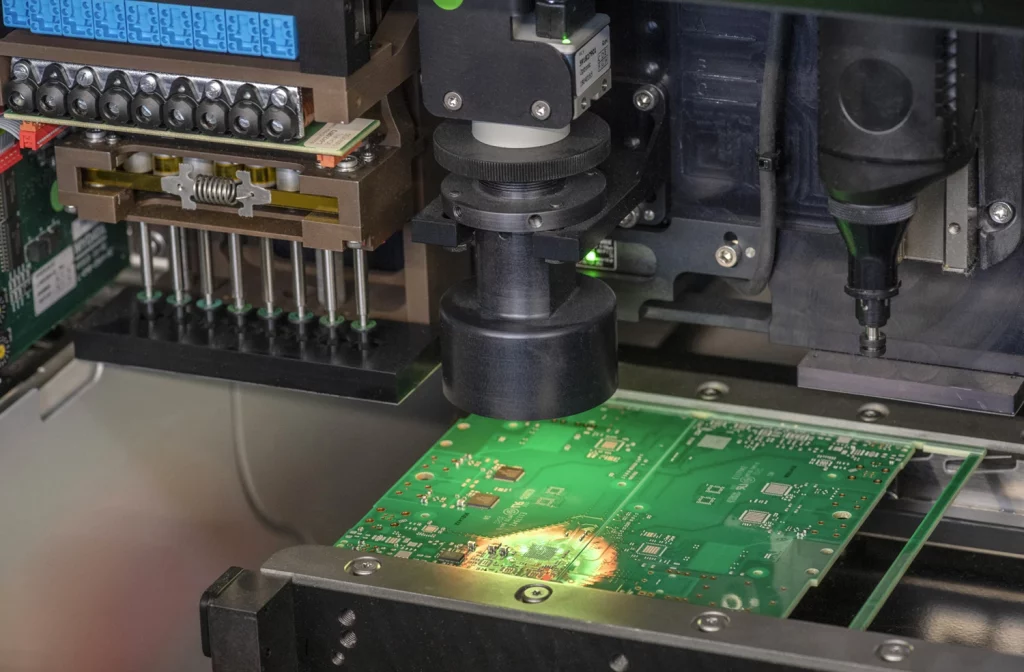

SMD assembly – fast and reliable

At our Munich site, we not only manufacture our own products, but are also happy to take your order.

We supply flexible PCB assembly – from prototypes to small series. Our modern infrastructure is optimized for fast product changeovers, so we look forward to even your most spontaneous challenges.

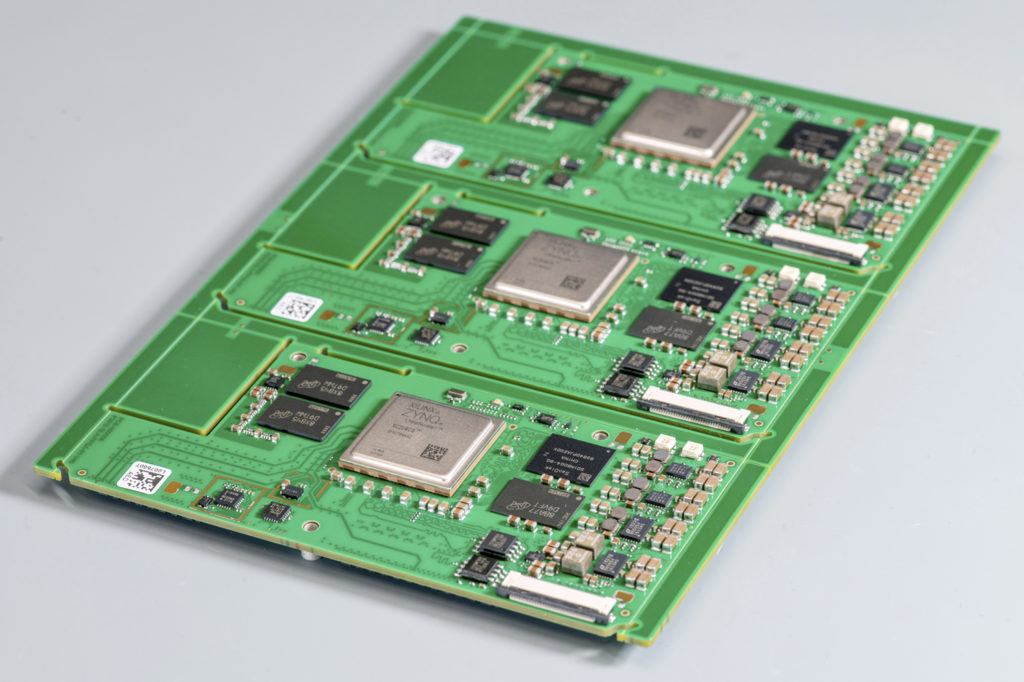

PCB Assembly: fast and flawless

from the first piece!

Device assembly, first-time operation and testing

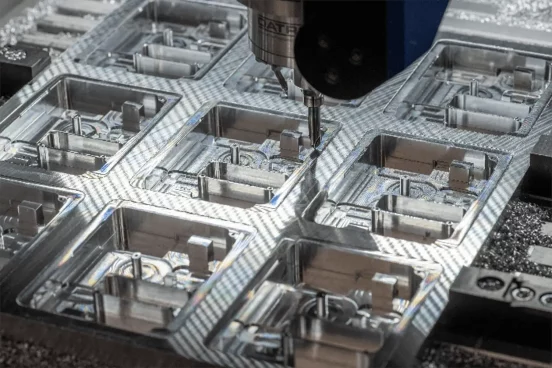

CNC milling

Laser engraving

Purchasing and warehousing

Contact us

How can we help you?

For further information on our automotive products and services, kindly contact us with your specific inquiry and we’ll get back to you as soon as possible.